MP-125

MP-125

sodium hypochlorite generator

Generating up to 125g/hr of equivalent Chlorine

Electrochlorination is the process of using only salt, water and electricity to produce a low strength concentration of Sodium Hypochlorite, which when dissolved into water produces the powerful disinfectant hypochlorous acid.

The AMPRO MP-125 is an environmentally friendly approach to generating a disinfectant on site and on demand. The process does not involve the use of toxic or hazardous chemicals to produce the sodium hypochlorite solution, removing the requirement to source and store hazardous disinfectant chemicals at site.

The MP-125 consists of minimal and modular components, which can be installed in almost anywhere water needs to be treated. The system requires very little maintenance, salt is topped up periodically and full system service is recommended on a yearly basis.

All AMPRO systems offer a high degree of safety with integral hydrogen degassing and continuous force air ventilation and monitoring whilst in operation.

KEY BENEFITS

-

Low hazard chemical

-

Broad spectrum disinfectant

-

Fast acting treatment

-

Automated process

-

Reduced chemical risks

-

Low cost of ownership

-

Minimal maintenance

-

Quick & Simple to install

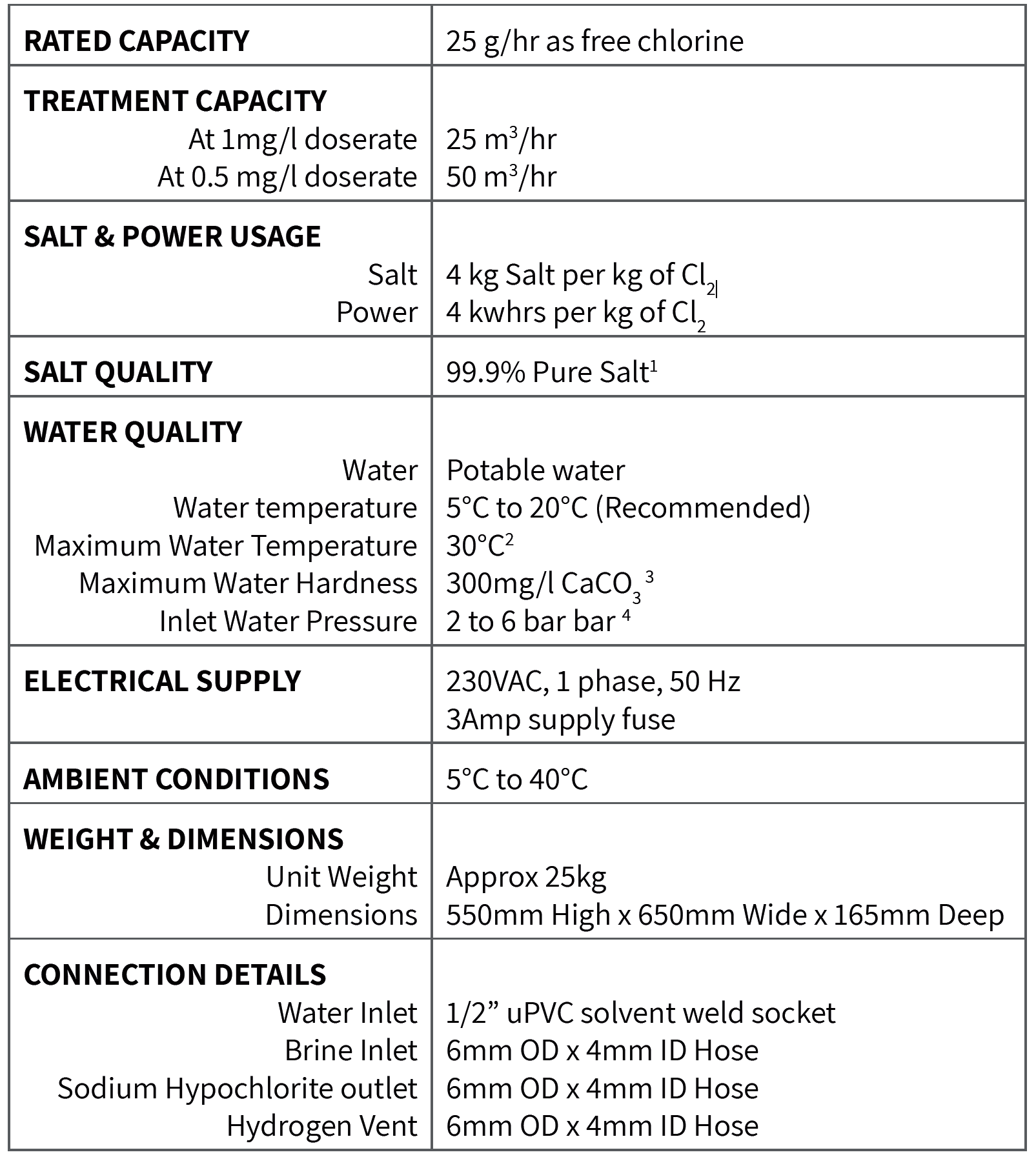

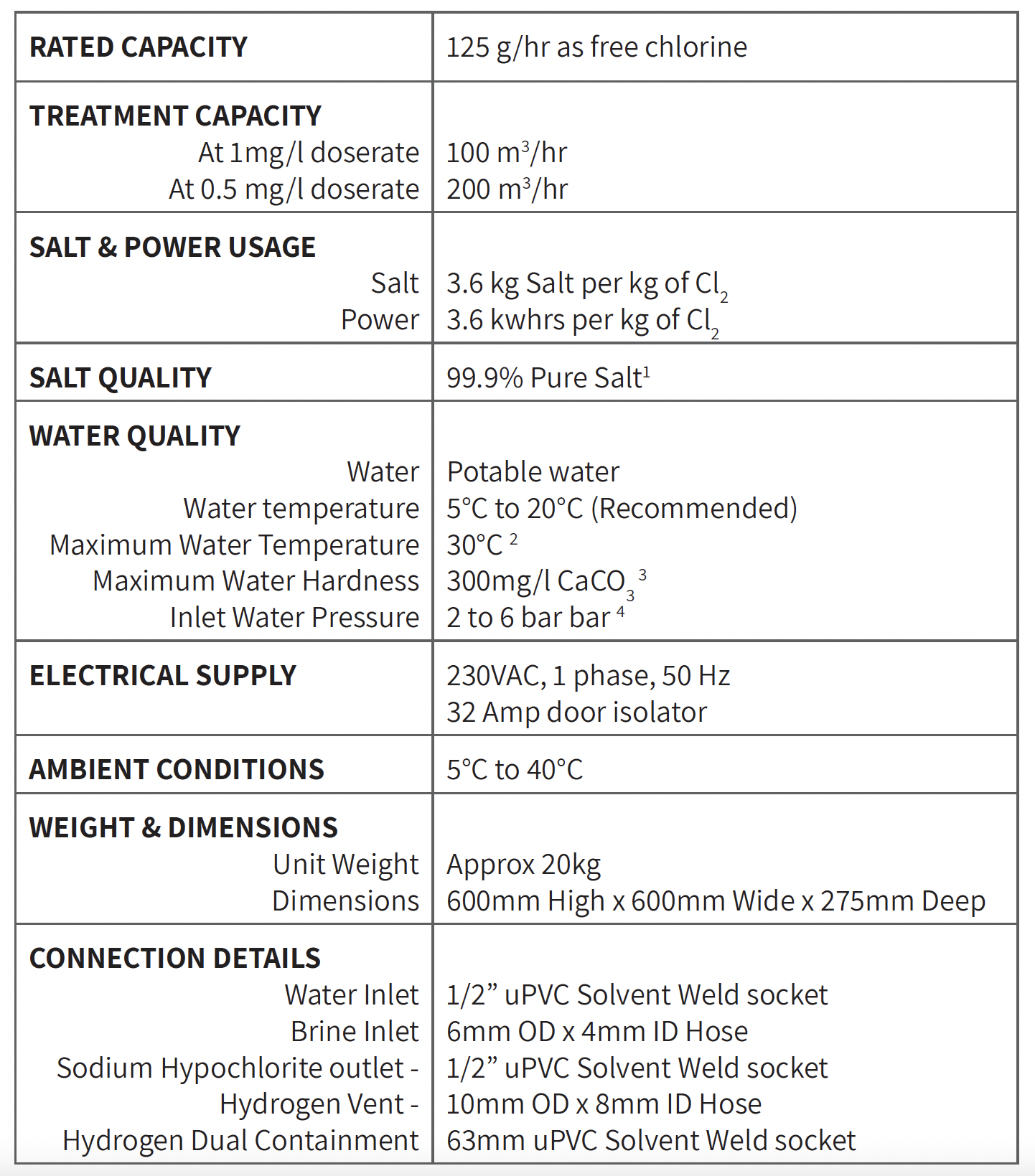

Product Specification

- for salt quality of lower specifi cation please consult with Prodose

- Water temperature above 35°C may reduce sodium hypochlorite concentration. Chiller may be required

- for water hardness greater than 20mg/l CaCo3 water softener is required

- Water pressure of 2 to 6 bar at inlet to water softener.

PRINCIPLE OF OPERATION

Once air flow is confirmed the water inlet solenoid valve opens, soft water flows and the brine dilution pump commences drawing brine from the brine storage tank. The diluted brine flows into the electrolytic cell where power is applied across a series of electrodes converting the brine into sodium hypochlorite. The solution flows into the degassing column where hydrogen is degassed before the sodium hypochlorite flows to the storage tank. The system stops when the top level in the Sodium Hypochlorite tank is reached.

Ready to order or need some help choosing the right product?

Contact our sales team today.