Why is Electrochlorination the best choice for swimming pool disinfection?All swimming pools should be regularly and thoroughly disinfected. This eliminates harmful pathogens that cause sickness in swimmers and prevents the growth of other biological organisms, such...

Why is Electrochlorination the Best Choice for Swimming Pool Disinfection?

Why is Electrochlorination the best choice for swimming pool disinfection?

All swimming pools should be regularly and thoroughly disinfected. This eliminates harmful pathogens that cause sickness in swimmers and prevents the growth of other biological organisms, such as algae. Commercial pools come in all shapes and sizes and there may be multiple pools on a single site, each one requiring tailored disinfection depending on water volume and usage.

There are several different pool disinfection techniques currently available to pool managers.

Chemical Pool Disinfection

Commercial chemicals such as sodium hypochlorite or calcium hypochlorite are often used for the pool disinfection process. These chemicals are highly effective, but they can present problems if stored or handled incorrectly. Maintaining a safe and constant chemical supply can also be expensive.

Sodium Hypochloriirte is made on a industrial scale by reacting caustic with chlorine gas. It is delivered to site either in 20 litre containers or as a pumped over delivery into site storage tanks. When added to a pool, it attacks the microbial cell walls of any viruses, bacteria and fungi, breaking them down and preventing them from reproducing. The sodium hypochlorite solution needs to be carefully stored and managed as it degrades over time, or if exposed to sunlight, high temperatures or vibrations. It is also a major irritant to human skin and eyes, so should only be handled by trained staff wearing protective gear.

Calcium hypochlorite (Ca(OCl)2), created by combining calcium oxide (lime) with chlorine gas, usually comes in tablet or granulated powder form. It is supplied in 45 kg containers. Measured doses are added to water to form hydrochloric acid, which works in the same way as Sodium Hypochlorite to destroy harmful organisms in the water. ‘Cal Hypo’ is easy to buy, transport and store in powdered form, and has a shelf life of 2-3 years.

It reacts to sunlight and it should be diluted so it won’t form liquid bleach. If misused or mishandled, cal hypo is also an irritant. Additionally, it adds calcium to the pool water and this may lead to calcium scaling on tiles and equipment over time.

Ultraviolet (UV) Pool Disinfection

Ultraviolet light rays have germicidal properties and are increasingly used to sanitise water, surfaces and even air supply, The UV light targets the DNA or RNA of algae, fungi, viruses, bacteria and any other micro-organisms in the water, preventing reproduction and growth. It’s environmentally friendly as it creates no chemical by-products. However, it can be expensive to install and needs to run 24/7. It won’t remove non-biological contaminants (such as excess chlorine or salts). It only works in clear water — cloudy water may need additional filtering before the UV disinfection can get to work. UV Radiation can remove

Looking for an easier way to generate Chlorine Dioxide on site?

Electrochlorination Disinfection

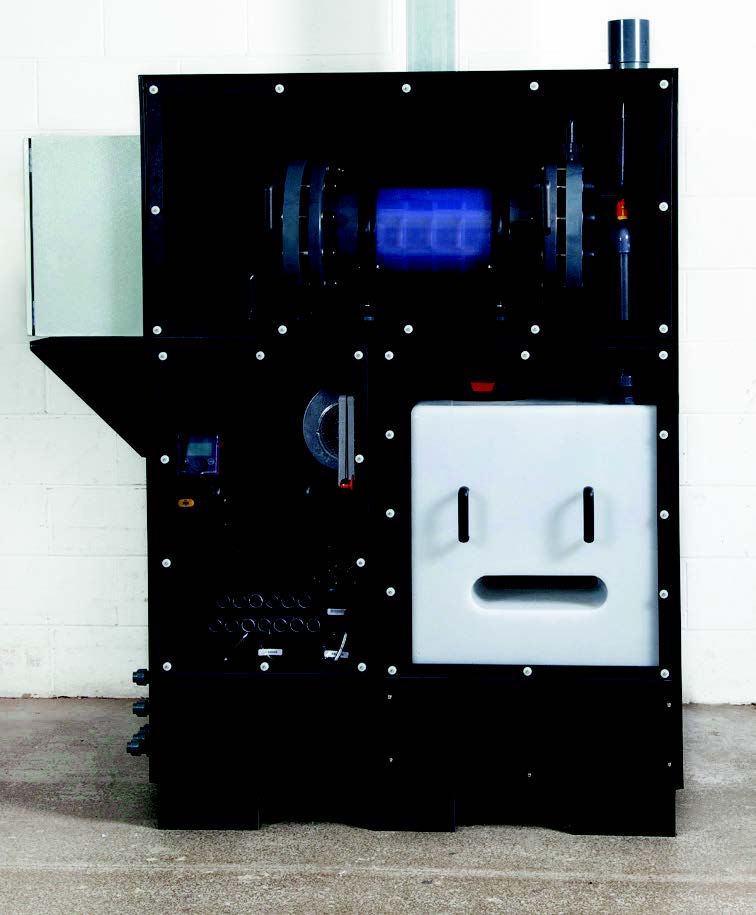

Electrochlorination is the process of generating Sodium Hypochlorite from a brine solution via the simple process of electrolysis. Electrolysis of brine is a tried and trusted technique and electrochlorinators have been sold for the disinfection of water for decades. The outlay cost for an electrochlorinator has come down over time, which now makes it a viable alternative to the continuous procurement of raw materials necessary for chemical pool disinfection.

How Does Electrochlorination Work?

An electrochlorinator generates Sodium Hypochlorite from a high quality salt. Several 25 kg bags of salt are added to a brine tank and mixed with softened water. Some of the salt dissolves in the water until it becomes a saturated brine solution i.e. no more salt can dissolve. This brine solution is then diluted to a 3% concentration where it passes through an electrolytic cell and produces Sodium Hypochlorite. The resultant Sodium Hypochlorite solution is stored in a small tank where it can be metered into a pool under the control of a pool controller. During the process a number of reactions take place inside the cell but they can be summarised as:

2NaCl + 2H2O → NaCl + NaClO + 2H2

The sodium hypochlorite generated is typically 0.7% solution strength. This electrolytic generated Sodium Hypochlorite is significantly lower strength than commercial hypochlorite (14-15%), which is a benefit for many applications including pool disinfection.

What Does Electrochlorination Cost?

One major advantage of generating Sodium Hypochlorite at site with an electrochlorinator is reduced costs. As a quick comparison:

- Each kg of chlorine generated by an electrochlorinator requires approx. 3.5kg of salt.

- A 20 litre container of 14%-15% Sodium Hypochlorite contains approx. 2.8 kg of Chlorine.

- A 45kg container of Calcium Hypochlorite (approx. 68% active ingredient) contains 30.6 kg of chlorine.

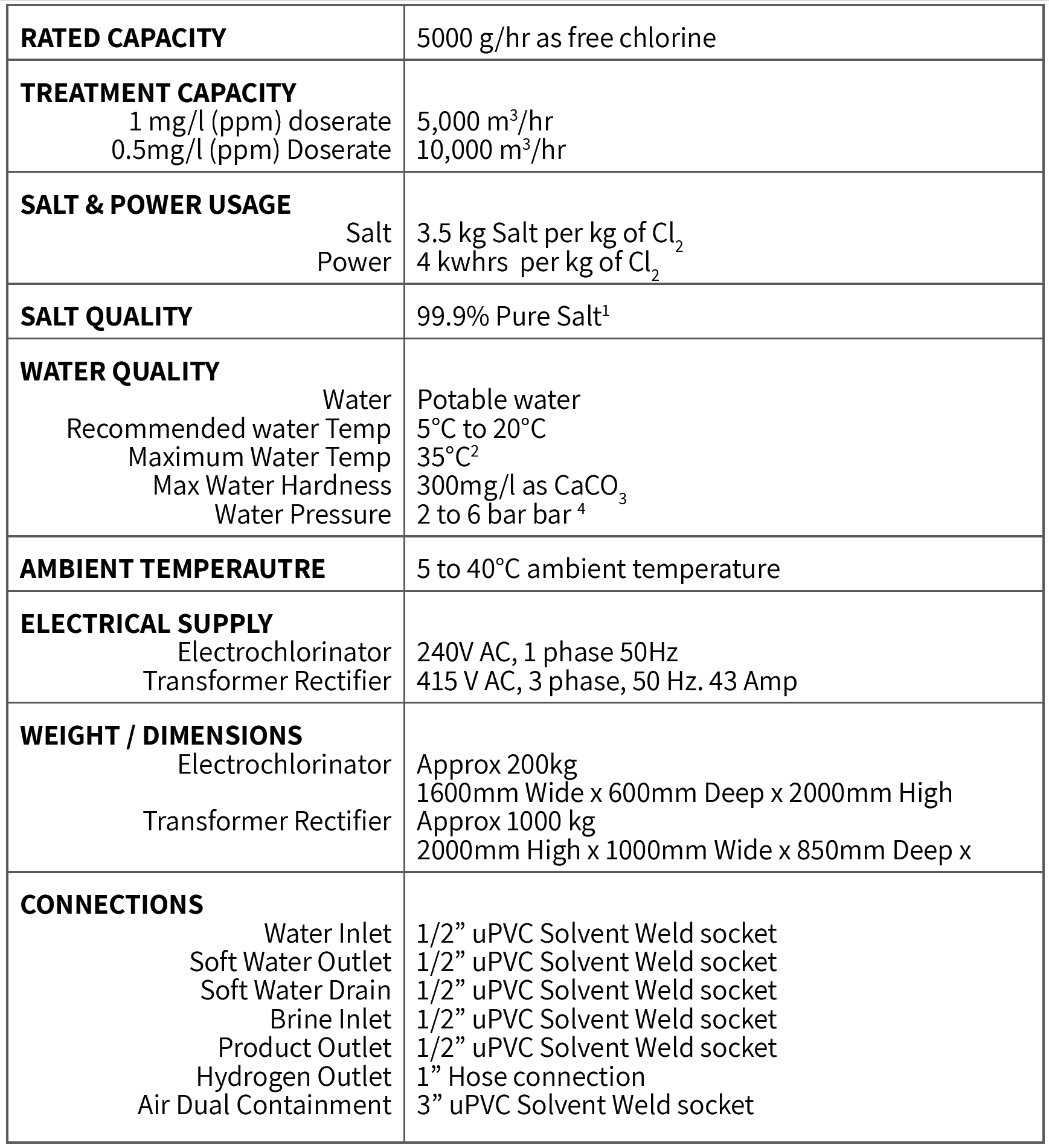

The following table shows the chemical costs in terms of salt to generate a single 45kg container of calcium hypochlorite and 20 litres of sodium hypochlorite:

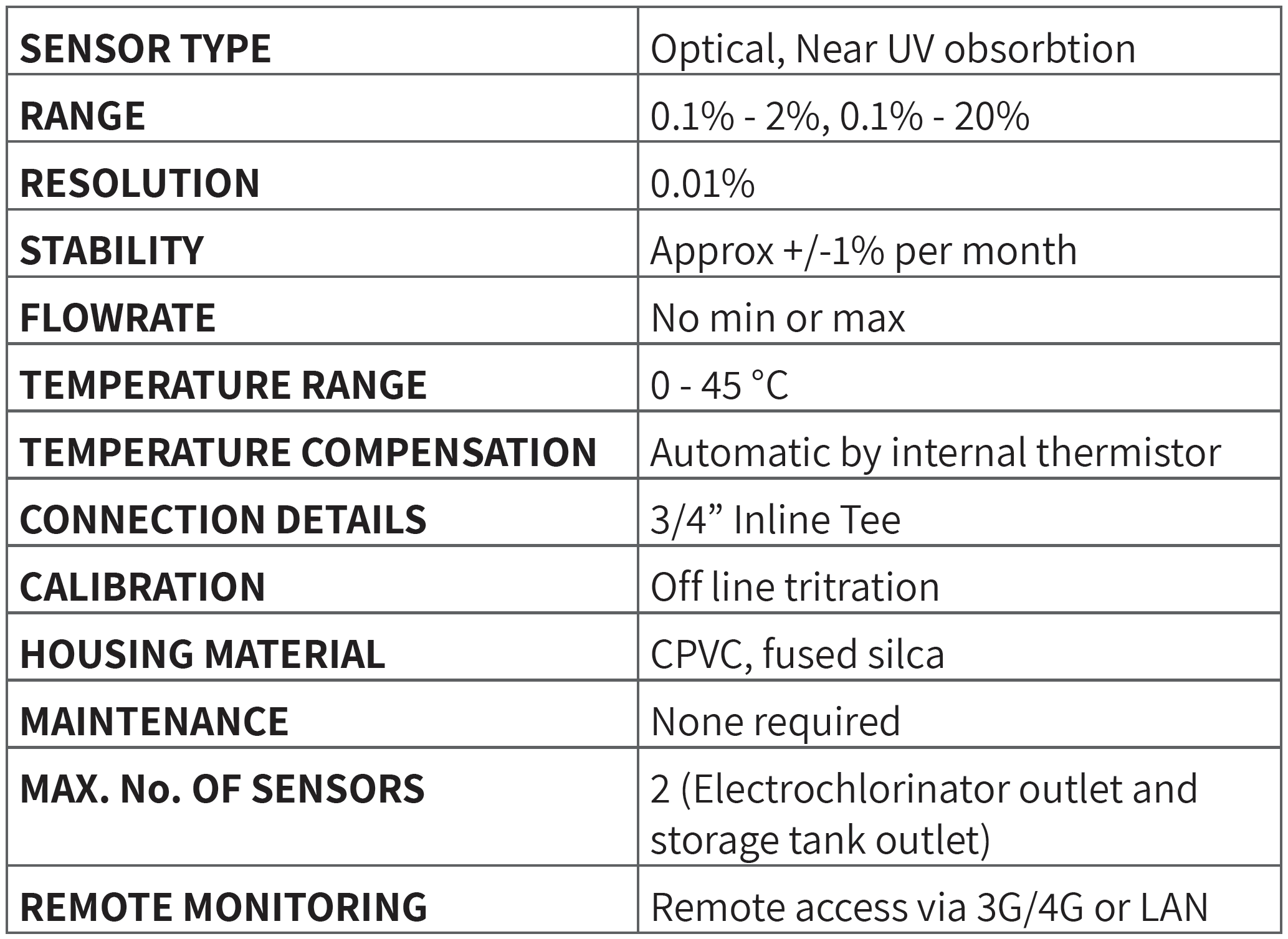

| Chemical | Equivalent Salt required | Cost1 |

| 45 kg tub of calcium hypochlorite | 107.1 kg | £24.63 |

| 20 litre container of Sodium Hypochlorite | 9.8kg | £2.25 |

- Based on the cost of a 25 kg bag of salt at £5.75.

From this table it’s easy to compare potential chemical costs against the equivalent costs of switching to an electrochlorinator. From this we are able to calculate the payback period for each site. This often demonstrates an immediate benefit on the Profit and Loss accounts as the capital cost of systems are normally ammortised over an asset’s lifetime.

So why is it better to generate Sodium Hypochlorite onsite? Sodium Hypochlorite from an electrochlorinator has several advantages over purchased chemicals. These can be summarised under the following headings:

RUNNING COST

The costs of salt versus commercial chemicals have already been discussed. There is clearly a lower running cost for pools using electrochlorination, which often generates a reasonable payback for the capital investment.

HEALTH & SAFETY

Commercial Sodium Hypochlorite is classed as hazardous at 5% concentration or higher. At 0.7% the electrolytically generated Sodium Hypochlorite is significantly safer in comparison to both commercial Sodium Hypochlorite and Calcium Hypochlorite. Lower COSHH risks for employees is a big benefit..

The only chemical handled by employees is salt. There no risk to employees to being exposed to salt, further reducing chemical risks within the plant room

The second risk is the elimination of the risk of filling the wrong tank, as may happen when using Sodium Hypochlorite or Calcium Hypochlorite. High risk incidents occur when acid is inadvertently mixed with sodium hypochlorite. This produces toxic chlorine gas. There is no such risk with an electrochlorinator as only one tank (acid tank) is ever filled manually.

CHEMICAL MANAGEMENT & PROCUREMENT

The only chemical required for the onsite generation of hypochlorite is salt. Salt is available in 25kg bags and delivered in pallet loads of up to 49 bags. Salt can be safely stored indefinitely in a range of temperatures, making it easy to procure and easy to store.

BUSINESS SUSTAINABILITY

Prices of commercial chemicals fluctuate,and they may become scarce or even unavailable. This affects the ongoing business operation of a swimming pool. If the water isn’t disinfected to established standards then the pool has to close. Even a short closure can affect revenue. Chemicals are part of the supply chain and their availability can be curtailed by the pandemic or other external factors, such as the closing of a factory or industrial action.

Salt is mined and refined in the UK and is produced in large quantities by several companies. It’s a standard commodity, stable in price. It is easy and low cost to buy ahead and simple to store in times of difficulty.

ENVIRONMENTAL GAINS

Salt is a readily available resource mined and refined in the UK and is delivered in its raw form. Chemicals such as Sodium Hypochlorite and Calcium Hypochlorite are nearly always imported from overseas, so there is a major environmental cost involved in their transport.

Why Use Prodose for Your Electrochlorination Needs?

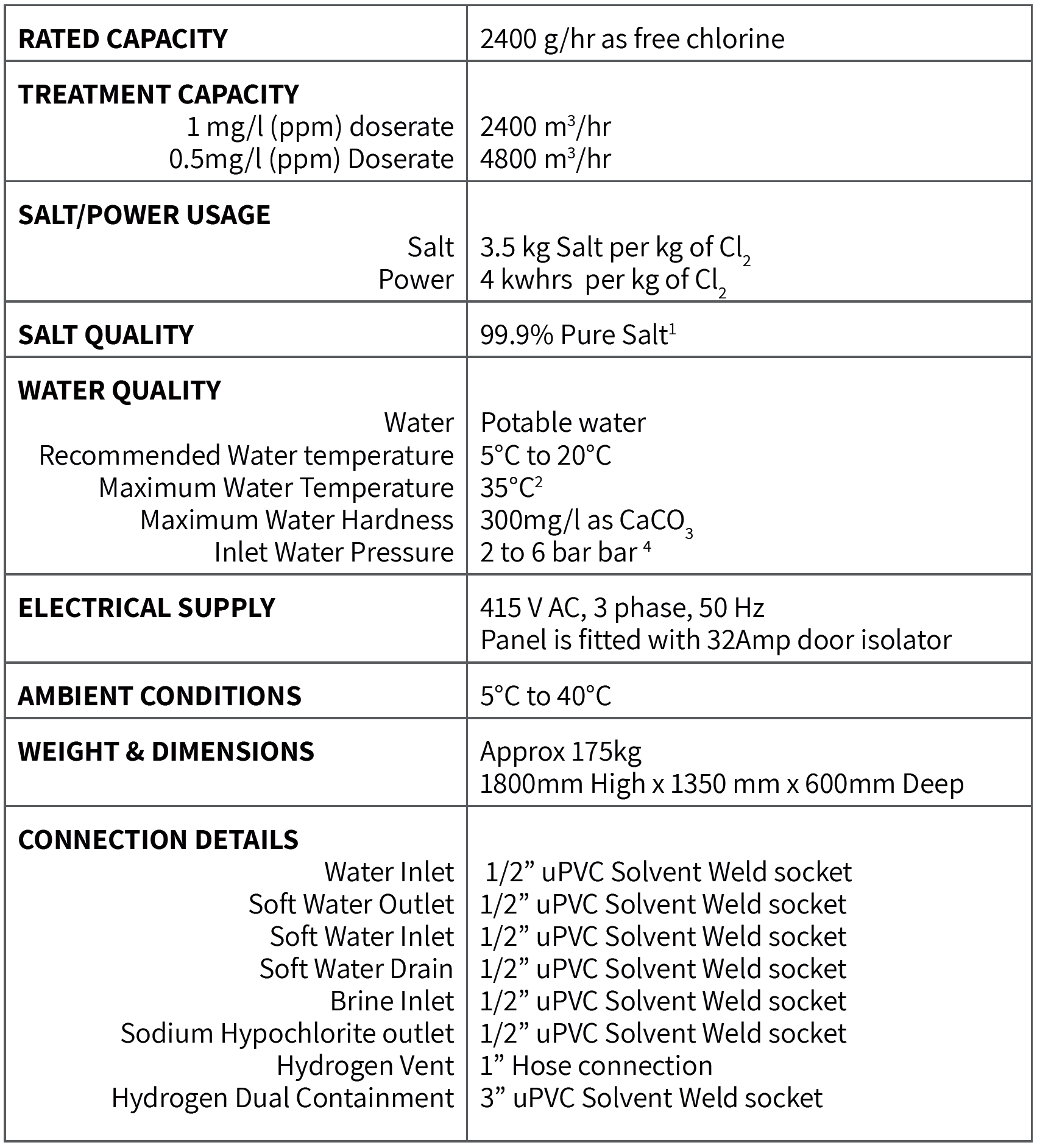

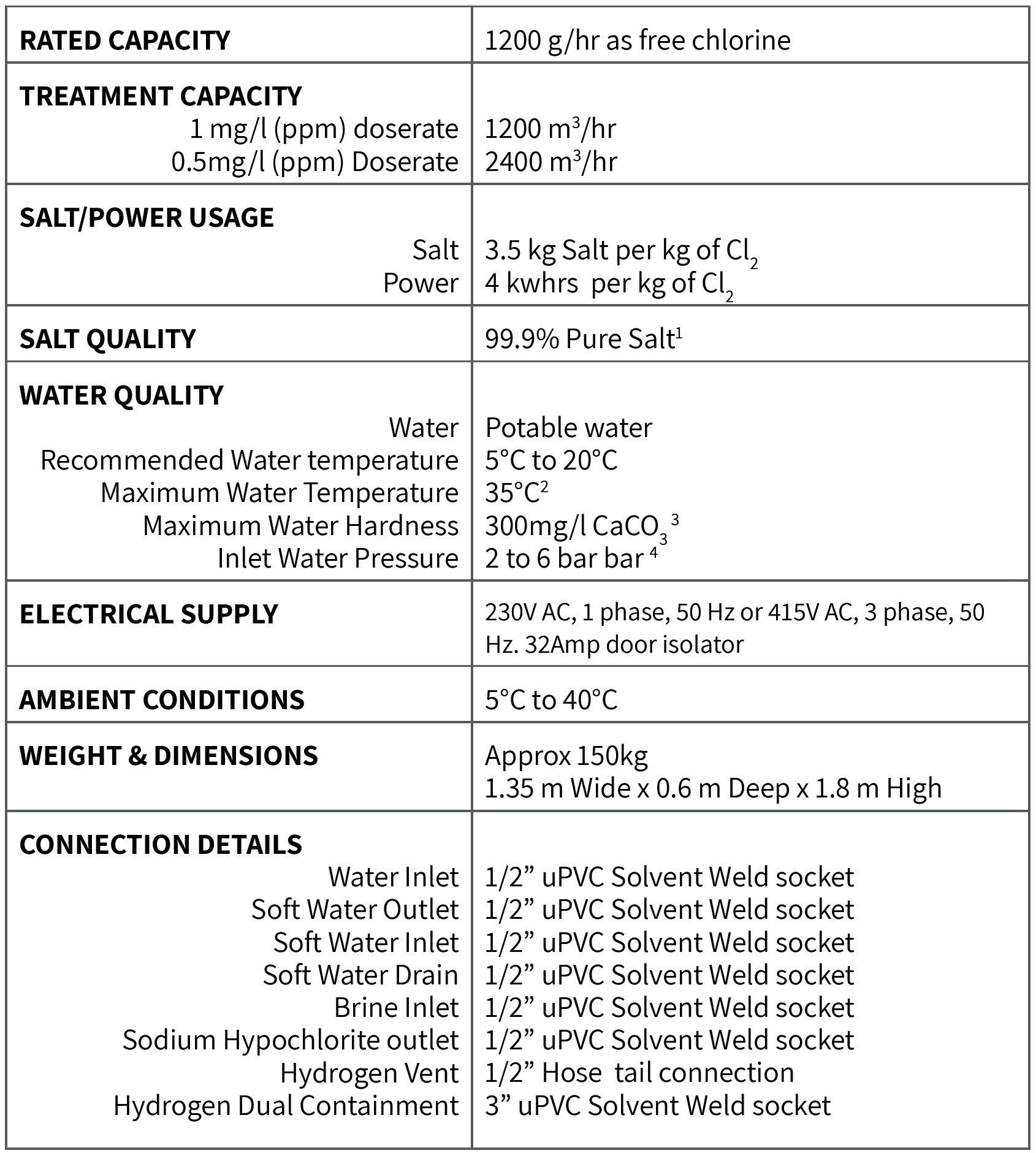

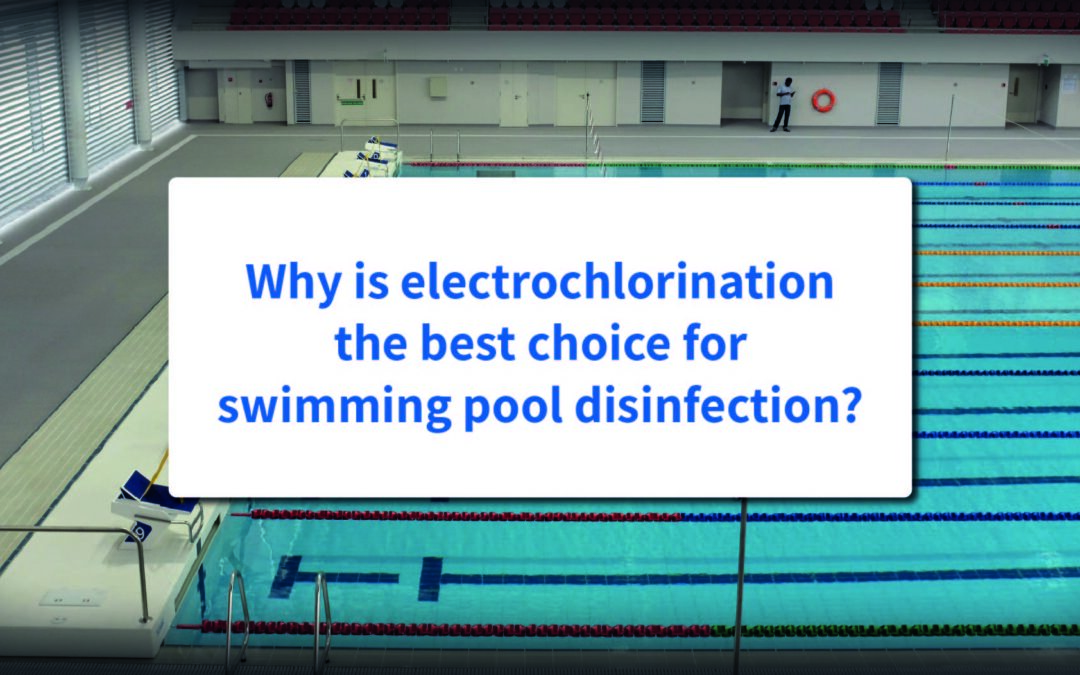

Prodose manufactures the Ampro range of highly cost effective and uniquely controllable electrochlorinators. We have built these systems to multiple specifications from more than a hundred UK and overseas projects, that include a range of different sized swimming pools. The range of Ampro electrochlorinators come with a complete after-sales support and if necessary can be installed by third parties.

As part of our customer commitment, we assess each swimming pool disinfection project individually as we pride ourselves on always aiming to specify the most suitable equipment to meet your requirements. Given we are not tied into any particular manufacturer or on commission to sell certain products means we are entirely impartial and can supply a range of equipment from different suppliers.

Why not take advantage of our specialist expertise with regard to electrochlorination? Our years of extensive experience in working with these systems ensures we are in a very strong position to assess your pool disinfection needs and advise you on the best solution.

If you are interested in finding out how Electrochlorination could be used for treatment of your swimming pool, please get in touch with us at Prodose. We’d be very happy to talk to you on a no-pressure basis.

Recent Articles

Why is Electrochlorination the Best Choice for Swimming Pool Disinfection?

What is the Electrochlorination Process?

What is the Electrochlorination process?Electrochlorination is the process of applying an electrical current to salt water to produce dilute sodium hypochlorite (bleach) and hydrogen gas. The resultant sodium hypochlorite solution contains between 0.7%-1% chlorine....

Chlorine Dioxide and Legionella Control

Chlorine Dioxide and Legionella ControlLegionella is a bacterium found in soil and water. When it occurs outdoors, it usually does so in low concentrations and doesn’t cause problems. However, when it grows inside artificial water systems, such as hot tubs, hot water...

Chlorine Dioxide and Water Treatment for Plant Nurseries

Chlorine Dioxide and Water Treatment for Plant NurseriesHorticultural facilities, such as plant nurseries, face many of the same water sanitation issues as their agricultural counterparts. These issues include keeping ornamental and food plants healthy, maintaining...

Keeping it clean: the use of Chlorine Dioxide in the Food and Beverage Sector

Keeping It Clean: the use of Chlorine Dioxide in the Food and Beverage SectorChlorine dioxide is rising in prominence as the best water treatment additive for the food and drinks industry. It’s powerful and economical, and may be a more practical solution for...

Chlorine Dioxide: the practical choice for water treatment in the UK

Find out about Chlorine Dioxide and why it makes such an effective water treatment for the food industry and other industrial practices.